Cooperation between ZMM and Blumenbecker

Long-standing partnership

With a production output of over 600 units a year ZMM Bulgaria is one of the world's largest manufacturers of universal lathes, pipe machining centres and CNC machines. Each unit that comes off the final inspection line at the Sliven plant represents nearly 70 years of experience in a production run that now stands at over 115,000 metalworking machines. Germany is one of more than 80 countries on the ZMM export list and Blumenbecker can look back on many years of an exclusive partnership with the Bulgarian company.

ZMM lathes are manufactured at four factories in Bulgaria employing more than 520 highly-skilled assembly workers and 230 engineers. The company is certified to DIN EN ISO 9001 and the machines are of course produced to current CE standards.

ZMM is continually investing in new production facilities and technologies. The product range now comprises over 50 different models and of course the production strategy has to be very client oriented to meet the different specification requirements of the customers.

Only high-quality components used

About 650 machines come off the production line at the Sliven plant every year. 'All are built using only components of the highest quality', stresses Martin Spiek, head of Blumenbecker's machine-tool competence centre. 'ZMM's other business partners include Siemens, SKF, Schaeffler, Fanuc, Fagor, Bison and Heidenhain.'

Blumenbecker wanted to be ZMM's German business partner right from the outset. What sets the company apart from many of its competitors is its cutting-edge technology, its flexible approach to supplying products that are tailored to customer requirements and the robust design of its machines. This means real security of investment for our clients. Even today you can still obtain spare parts for machines that were built in the 1970s.

Blumenbecker has been a byword for machine tools for many years. The company's advisory expertise, its wide selection of machines, which includes well-known manufacturers as well as its own-brand range, and the excellent price-performance ratio are all factors that have come to make Blumenbecker a highly sought-after business partner. The company's competence centre also includes a wide range of machine tools fully set up for demonstration purposes.

Numerous model lines

The collaboration between ZMM and Blumenbecker has many advantages for the customers. They not only benefit from the in-depth expertise but can also depend on a fast and efficient after-sales response, including of course on-site commissioning of their machine.

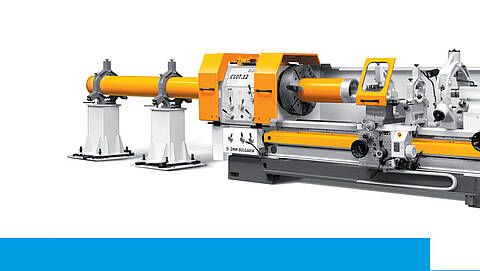

The technical advantages of ZMM universal lathes now enjoy a worldwide reputation. They are all of solid, cast-iron construction and feature a large bed width, which helps reduce vibration and ensures maximum stability. Even the standard machines have an impressively high power rating. All conventional models can be supplied with a choice of manually controlled or stepless spindle drive power with variable speed regulation.

The Blumenbecker range includes ZMM lathes with swing diameters of 330 to 1410 mm and a distance between centres of 500 to 10 000 mm. There are also special pipe machining centres for the oil and gas industries with twin feeds and spindle bores of up to 358 mm diameter. The range includes four model lines of high-tech CNC machines with swing diameters of 580 to 1250 mm.