Machine Vision

More than cameras

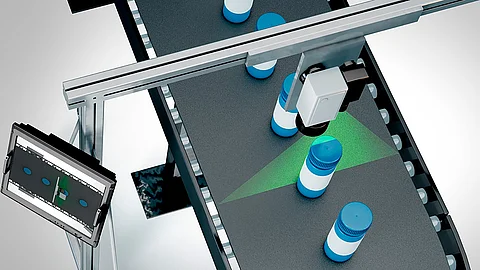

Sensors and industrial cameras have opened up new perspectives in the automation of production lines. Blumenbecker's machine vision systems are used for applications such as:

- measurement (measurement of specific product dimensions, volume measurement, etc.)

- product inspections (checking the presence and correct position of all parts of the assembly, e.g. during assembly)

- product identification (barcode and 2D code reading, product type identification based on shapes, sizes and other features)

- product sorting (e.g. sorting of packaged chocolates by type of packaging, etc.)

- robot navigation (determining the position of the product and using its coordinates for palletizing, welding, gluing and other activities)

Sensors and industrial cameras are often used for quality control. They ensure high product quality, strengthen customer confidence in products and reduce complaints.

Important parameters of industrial cameras

Many of today's industrial cameras are equipped with their own processor and the ability to communicate over industrial guidelines (profinet, ethernet I/P, DIO,...). Thus, there is no need to use a computer for common applications. This type of camera is called a "smart camera". There is a great variability in the choice of the appropriate camera type (2D, 3D, mono, color, resolution, size, communication options,...) and accessories (lighting, filters,...). For specific applications, the use of a camera and an industrial computer is common.

For special applications where, for example, it is difficult to distinguish all parts of the product, different types of cameras can be combined (e.g. a 3D profiler with a 2D colour camera).

Manufacturer-independent solution from Blumenbecker for greater reliability and speed

The reliability of measurement/detection/identification depends not only on the quality and resolution of the cameras or sensors, but also on the quality of the software that processes the data.

Blumenbecker has developed proprietary software for its machine vision systems that maximizes sensor and camera performance.

The software supports the identification of:

- Geometric features (e.g. correct length of a bar)

- Colour features (e.g. correct paper hue)

- Position data (e.g. correct location of a part)

- Temperatures (e.g. during glass production)